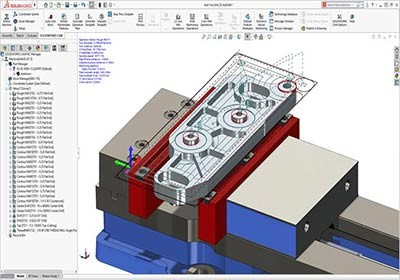

SOLIDWORKS CAM can employ a machining technique where a three-axis milling program is executed with the cutting tool locked in a tilted position using the five-axis machine's two rotational axes.Īny modifications made to the SOLIDWORKS design are automatically updated in SOLIDWORKS CAM, which eliminates time consuming CAM system rework due to design alterations.It’s almost time to head to Los Angeles for SOLIDWORKS World 2018 and for many attendees, it will be a welcome relief from winter weather.

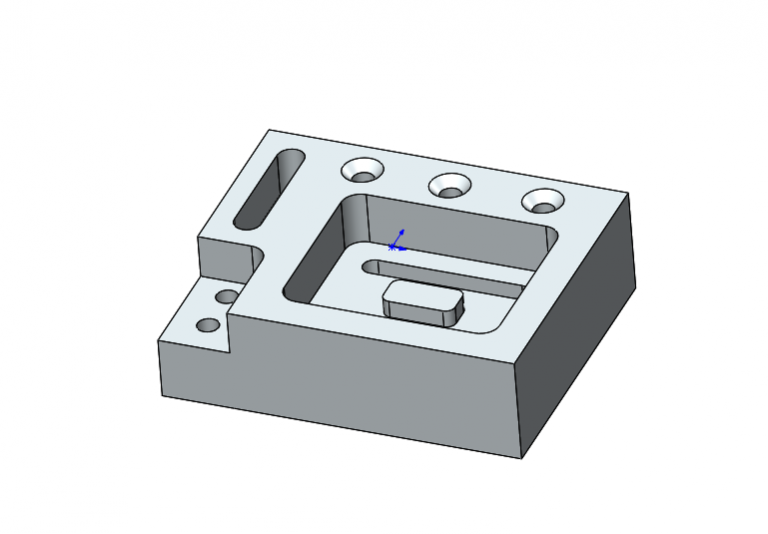

SOLIDWORKS Cam utilizes Volumill for high performance roughing capabilities which allows programmers to reduce cycle times by up to 80%, reduce programming times by up to 50% and increase Tool Life by up to 500%. SOLIDWORKS CAM has turning capabilities that include face rough and finish, rough and finish turn, groove rough and finish, rough and finish bore, cut-off, ID and OD threading, and drill, and tap on center.Īutomate machine time calculation and compare it to traditional methods for ensuring all aspects of a part are accounted for ahead of time before committing to production. Reading tolerances and surface finishes will help you to make decisions about how to manufacture your product. Model Based Definition (MBD) is leveraged to ensure machining strategies are automatically adjusted based on tolerance specifications. SOLIDWORKS CAM includes automatic roughing, finishing, thread milling, face milling and single point (drilling, boring, reaming, tapping) cycles.Ĭapture your Best Practices into a company owned databaseSOLIDWORKS CAM will automatically select your machining strategies, tools, feeds & speeds Helps new programmers to quickly become productive With patented Automatic Feature Recognition (AFR) technology, the SOLIDWORKS CAM can recognize 20+ types of machinable features on parts such as holes, slots and pockets.

0 kommentar(er)

0 kommentar(er)